Prolink

Real-Time Data Collection to Ensure Product Quality in Manufacturing

Prolink from Minitab is a comprehensive solution for quality monitoring in the manufacturing industry – from automated and standardised data collection to real-time analysis and automated reporting to predictive analytics. Prolink is aimed at quality managers, engineers and manufacturing teams who want to drive their production processes forward through data-driven decisions and continuous data improvement.

The powerful solutions in the Prolink product range are divided into four solution packages, depending on how thoroughly manufacturing processes are to be monitored and then analysed, which are geared towards a specific part of the individual quality journey.

Quickly ready for use

- Connection to more than 320 devices of inspection equipment – no complex configuration required

- Performance visualisation in real-time by means of charts, dashboards and alerts

Easy to use

- Standardised quality data across devices, teams and locations

- Avoidance of manual errors during data entry through seamless data integration

Ready for immediate use

- Faster decisions due to reliable, up-to-date data

- Industry-leading analyses for continuous process improvement

Prolink Collect – The Solution for Automated Data Collection by Any Device

The Prolink Collect solution collects data from various devices, for example, coordinate measuring machines (CMM) and programmable logic controller (PLC). Hundreds of drivers enable data transfer to SPC tools in real-time. The Collect solution for automated real-time data collection eliminates manual entry, reduces errors and provides immediate insights into data.

The Prolink Collect solution includes:

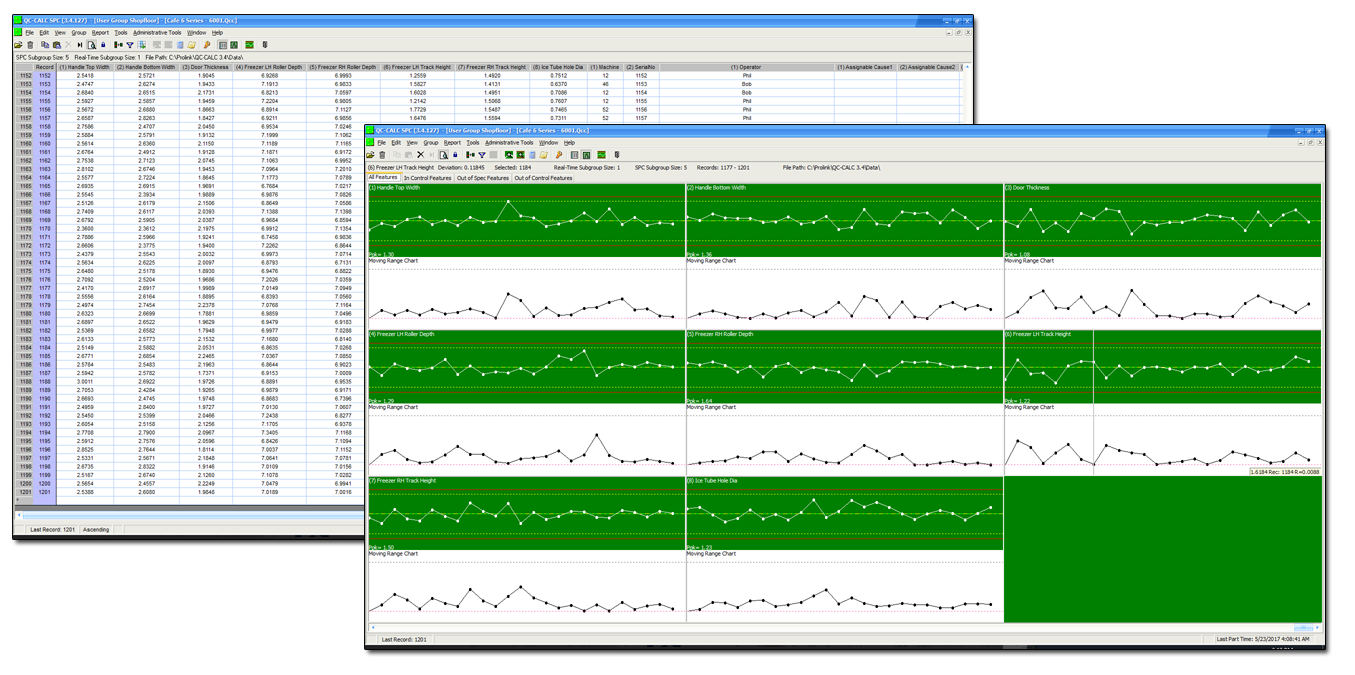

- QC-CALC Real-Time

Real-time data collection and display by CMMs (coordinate measuring machines) and video CMMs - QC-CALC Monitor

Anzeige der Messdaten aus der Netzwerkdatenbank in Echtzeit - QC-PLC

Display of measuring data from the network database in real-time - GageStation

Data collection by gages and transfer to QC-CALC Real-Time

Prolink Control – The Solution for Process Control with Real-Time SPC

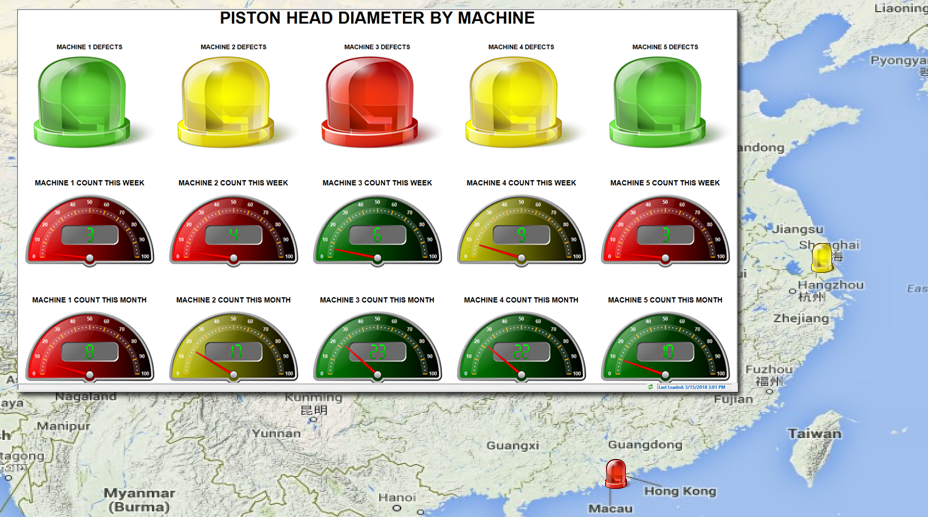

The Prolink Control solution is designed for active monitoring of manufacturing processes. It uses the data collected by gages to analyse processes in real-time using the methods of statistical process control (SPC). Live dashboards, interactive SPC programmes and automated alerts enable deviations from the optimal state and quality problems to be detected at an early stage.

The Prolink Control solution includes:

- QC-CALC SPC

Interactive tool for automated SPC reporting and data visualisation in real-time - QC-Mobile

Access to real-time reports and dashboards via web browser on any end device - QC-Alert

Automated alert software to trigger alerts in manufacturing by definable triggers

Prolink Optimize – The Solution for Automated Reporting

The Prolink Optimize solution automates report generation and integrates the collected data by connecting directly to software like Minitab, JMP or Excel. The time required for documentation is reduced, and reports can be standardised across locations to accelerate the sharing of insights within the company.

The Prolink Optimize solution includes:

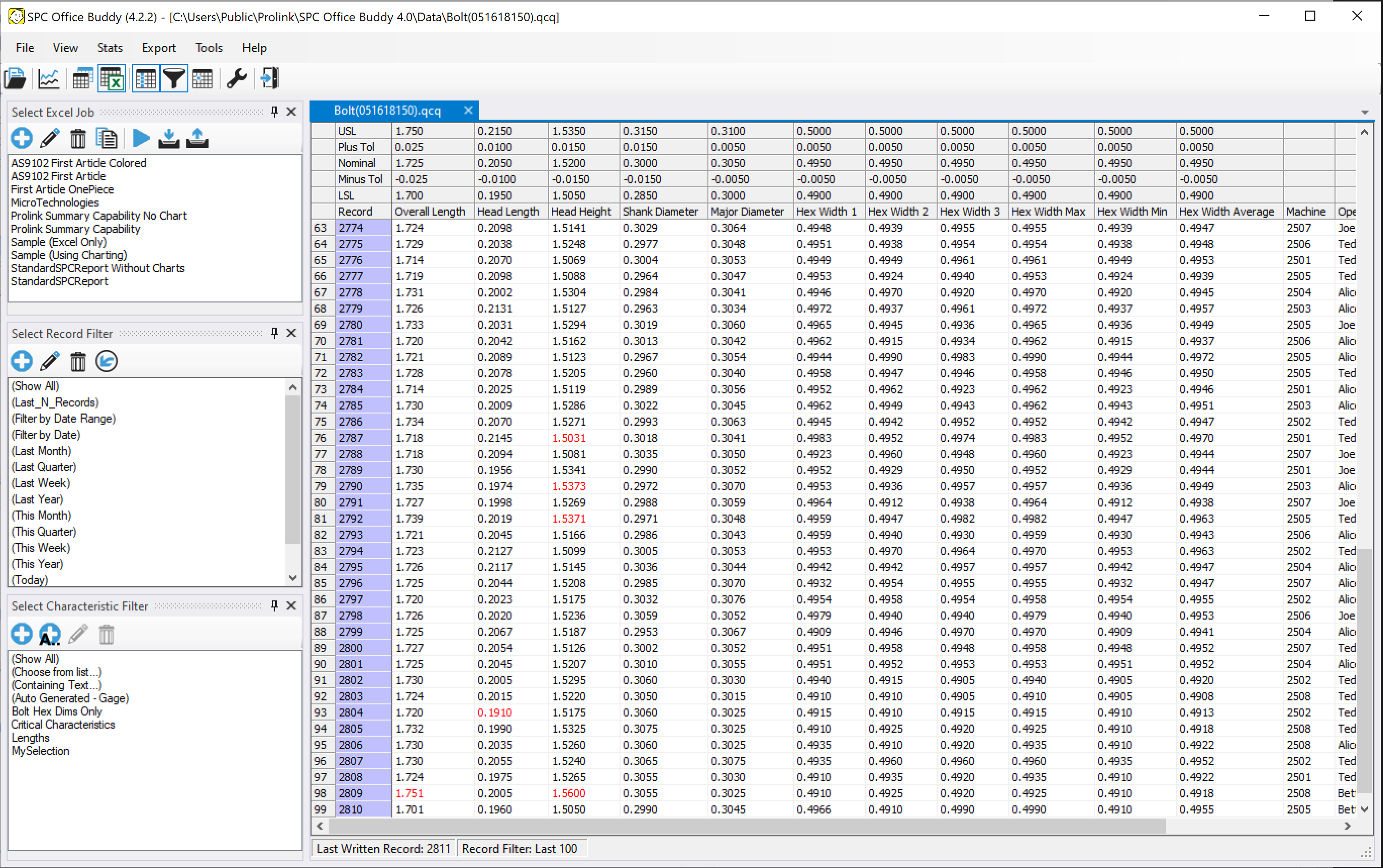

- SPC Office Pro (former SPC Office Buddy)

Data reporting software, which can be integrated directly in Minitab, JMP® or Microsoft Excel®

Prolink Insights – The Solution for Advanced Analyses

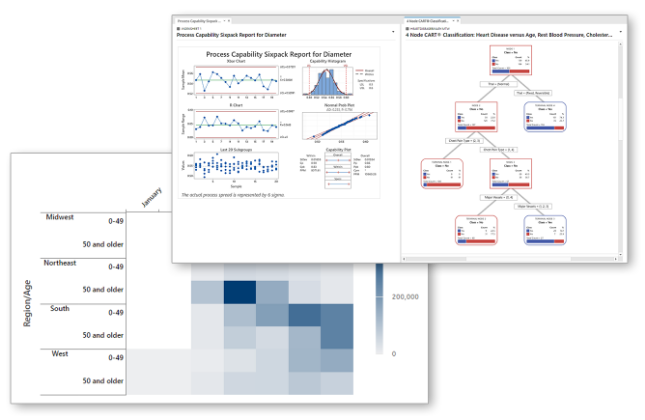

The Prolink Insights solution goes beyond simple manufacturing monitoring by combining real-time data collection with the advanced analytical capabilities of Minitab Statistical Software, covering everything from reliability engineering and product development to business analytics.

The Prolink Insights solution includes:

- SPC Office Pro (former SPC Office Buddy)

Data reporting software, which can be integrated directly in Minitab, JMP or Excel - Minitab Statistical Software

Software for quality statistics, business analytics and intelligence and data modelling

Your advantage with Prolink by ADDITIVE/h2>

We support you all the way – from the individual product selection to the implementation.

Our team of experts is always available for a personal product presentation or further information about the Prolink solution. We are happy to provide direct, fast and targeted advice by phone at +49 6032 34956 - 132 or by e-mail to