SPM in Action

Finding the root cause of excessive variation

Identifying which factors are contributing to the excessive variation in a manufacturing chemical process.

Using the CART Modeling Engine, SPM's decision tree algorithm that takes categorical data to predict a qualitative value, historical data can be segmented into a set of yes/no rules. This segmentation splits the response (Y) variable into partitions based on the predictor (X) settings. In the example below, out of the many variables that were run in CART, one predictor – production rate – is a large contributor to a point falling outside the production control limits.

Continually growing or "pruning" the CART tree will quickly identify additional causes of the excessive variability in this process. Once narrowed down to a few vital X's, controls can be put in place to reduce the chance of falling out of process specifications.

Determining what factors are correlated to manufacturing defects

Quickly uncover what factors in a manufacturing process are predictive of defects in production

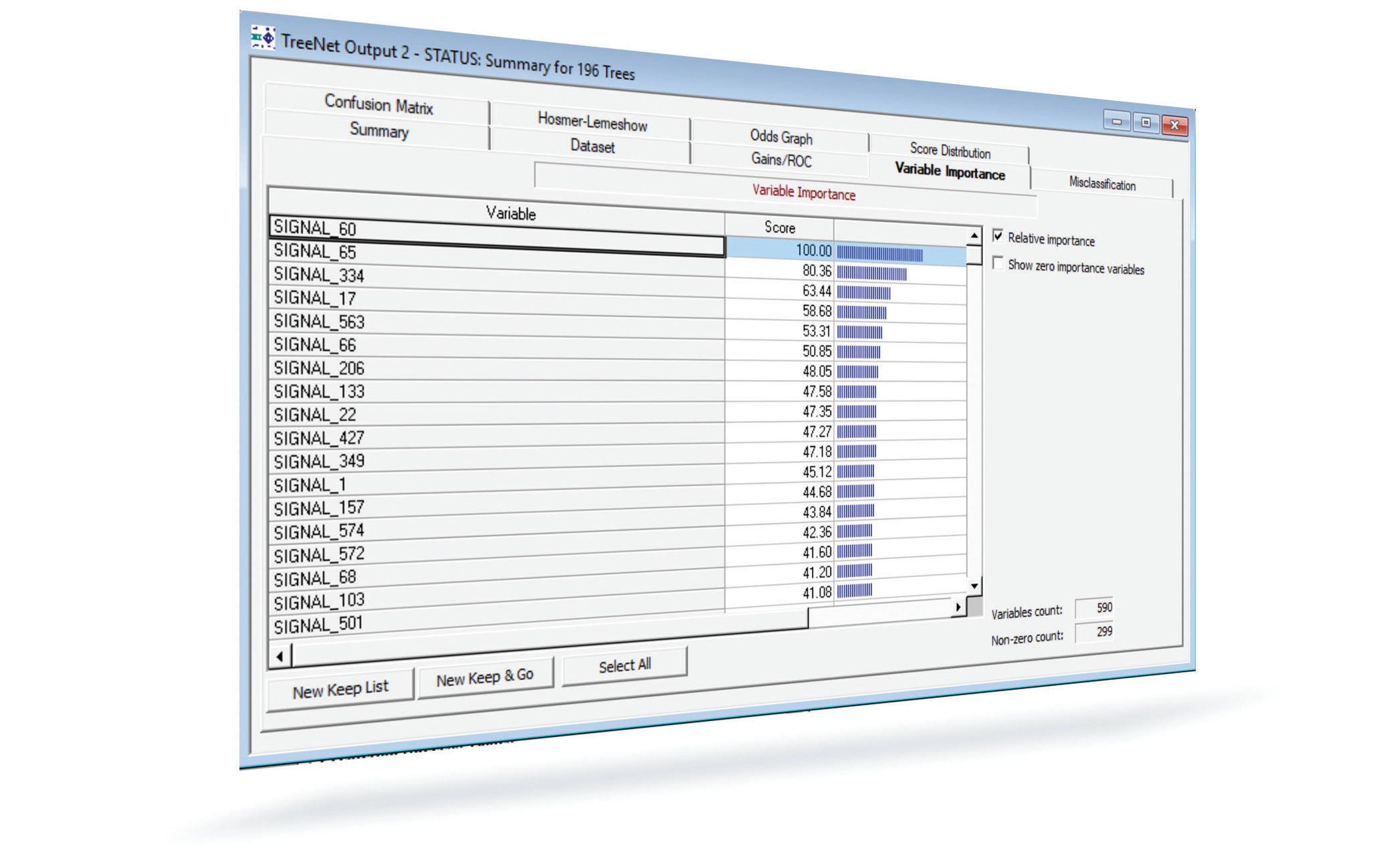

SPM's TreeNet Modeling Engine will generate the probability of a defect based on the variables (signals) supplied. Using the Automate Shaving feature in TreeNet, we can quickly narrow down 590 variables associated to the manufacturing process to 299 key factors that show a correlation with defects in production within minutes.

TreeNet Modeling Engine can quickly narrow down the variables that make the most impact and visually illustrate the relationship between the likelihood of a defect and the identified variables to draft a preventative action plan.